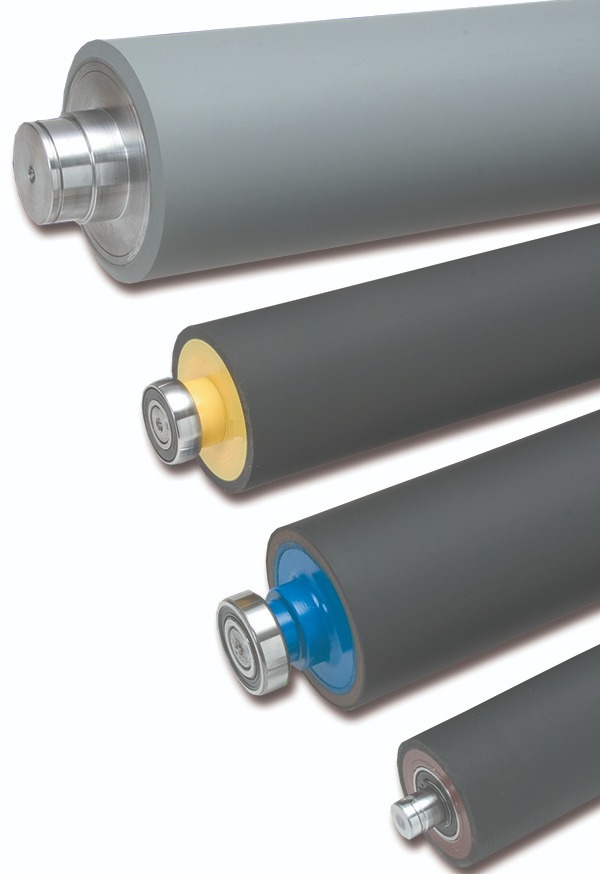

Lamination Rubber Roller

Price 10000.0 INR/ Piece

Lamination Rubber Roller Specification

- Usage

- Industrial

- Material

- Rubber

- Size

- Standard Sizes

- Product Type

- Lamination Rubber Roller

- Color

- All Color

- Feature

- Good Quality

Lamination Rubber Roller Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1000 Pieces Per Month

- Delivery Time

- 7 Days

About Lamination Rubber Roller

Lamination Rubber Rollers

Cooling Rollercomes with a hard chrome plated surface & Rubber coated roller. Cooled water passing through its Rotary joint cools the hard chrome plated surface area of the Roll. Standard Cooling Roll cools the contact area that touches the web materials. There are different types of Cooling Rolls like single shell, double shell jacketed type, spiral type. The Surface Cooling Roller results in varying effects in different type of Cooling Rolls. Rotary Cooling Roller has a shaft with inside hole to fix rotary joint. Bigger shaft diameter is recommended to avoid breakage of end shafts as end shaft having inside hole and uneven alignment or heavy tension on shaft result brakeage so bigger shaft diameter is recommended. We are called upon as one of the major Industrial Cooling Roller Manufacturers in Gujarat(india).

For hot laminating rollers (up to 220oC), we would recommend using a high-release silicone compound, as this compound is capable of withstanding such temperatures & non sticky properties.

For hot lamination rollers, where temperatures will not exceed 150oC (and high load, abrasion and wear are considerations), then we would recommend using a synthetic rubber compound. These could include Hypalon, Carboxylated Nitrile and EPDM.

Lamination applications, include:

Quality Construction for Reliable Performance

Our lamination rubber rollers are crafted from premium rubber materials, delivering consistent and reliable quality. They resist wear and deformation, ensuring long-term usage even in demanding industrial environments. With a focus on durability, each roller upholds our reputation as a trusted manufacturer in India.

Flexible Sizing and Color Options

Available in standard sizes and all color variations, our rollers are adaptable to a wide range of applications. This flexibility allows for easy replacement in existing machinery, minimizing downtime and maintaining production flow in your facility.

FAQs of Lamination Rubber Roller:

Q: How are your lamination rubber rollers used in industrial applications?

A: Our lamination rubber rollers are designed for industrial settings where they are used to apply uniform pressure during the lamination process. This ensures smooth adhesion and minimizes defects across a wide range of materials.Q: What materials are used in your rubber rollers and how do they benefit the user?

A: We use high-quality rubber in our rollers to offer superior elasticity, wear resistance, and longevity. This results in fewer replacements and lower maintenance costs for industrial users.Q: When should I replace my lamination rubber roller?

A: You should consider replacing your rubber roller if you notice irregular lamination, physical damage, or significant wear affecting performance. Regular inspections help ensure optimal output and extend the life of your machinery.Q: Where are the lamination rubber rollers manufactured and supplied from?

A: Our rollers are manufactured and supplied from India, meeting rigorous standards to ensure dependable quality and prompt service nationwide and internationally.Q: What is the process for customizing roller size or color?

A: Although standard sizes and colors are readily available, you can contact us directly to discuss customization options. Our team will guide you through specification requirements and estimated lead times.Q: How do I benefit from using your lamination rubber rollers in my facility?

A: By choosing our rollers, you benefit from high performance, reduced downtime due to durable construction, easy maintenance, and product versatility to fit various industrial lamination applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Roller Category

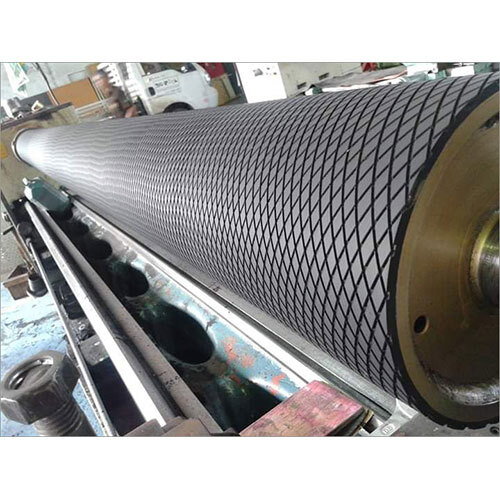

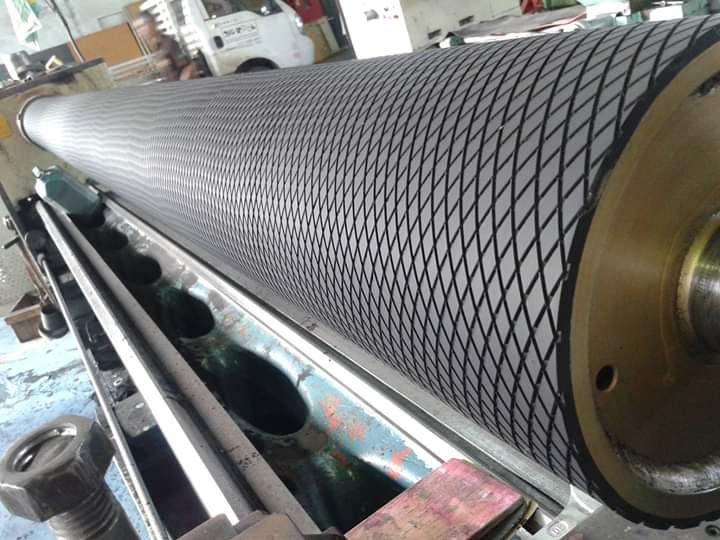

Diamond Groove Roller

Price 22000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Feature : High Quality

Size : As per buyer's requirement

Usage : Industrial

Material : Rubber

Flexo And Gravure Rubber Roller

Price 5000.0 INR / Piece

Minimum Order Quantity : 5 Pieces

Feature : Premium Quality

Size : Various Available

Usage : Industrial

Material : Polyurethane Rubber

Printing Machine Rubber Roller

Price 4000.0 INR / Piece

Minimum Order Quantity : 5 Pieces

Feature : Premium Quality

Size : Various Available

Usage : Industrial

Material : Polyurethane Rubber

Spiral Straight Groove Rollers

Price 8000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : Good Quality

Size : Standard Sizes

Usage : Industrial

Material : Rubber

Send Inquiry

Send Inquiry